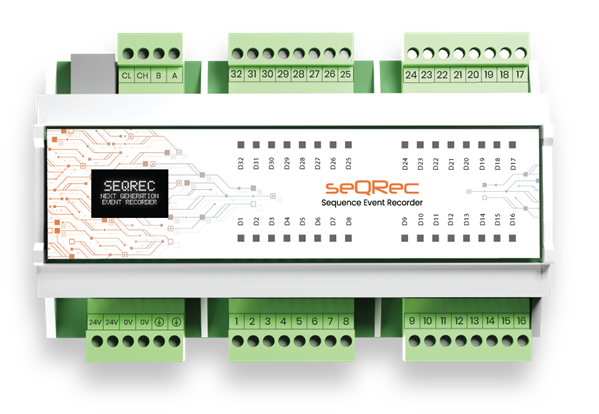

Sequence Event Recorder (SER)

The SeQRec Sequence Event Recorder (SER) is a state-of-the-art, highly reliable event and alarm management system designed to offer precise monitoring for industrial environments. This advanced recorder boasts a time-stamping resolution faster than 1 µss for accurate tracking of event occurrences, ensuring real-time synchronization through NTP (Network Time Protocol).

With a robust hardware platform built to withstand the toughest industrial conditions, the SeQRec is designed for capturing and recording relay outputs for immediate action. This allows for detailed post-event analysis to pinpoint the root cause of failures, enhancing operational efficiency and plant reliability.

Key Features & Benefits

High Precision Recording

Extensive Event Logging Capacity

Integrated Control Features

Flexible Connectivity

Wide Range of Inputs & Protection

Energy Efficiency & Safety

Extreme Environmental Resilience

Applications

Critical Event Monitoring

Event Reporting

Post-Event Analysis

Real World Scenarios

Data Centers

Data centers rely on uninterrupted power supply (UPS), power distribution units (PDUs), and backup generators. Any power event or failure can cause massive downtime, leading to financial losses.

How SER Helps

- Power Failure Analysis: Records the exact sequence of power failures, such as UPS malfunction or generator startup delay.

- Root Cause Identification: Helps in identifying if the fault originated from the grid, switchgear, or internal distribution system.

- Load Shedding Optimization:Provides historical event logs to optimize power management during high-demand periods.

Critical Power Management

Industrial plants (e.g., manufacturing, oil & gas, chemical processing) have high power demands with critical machinery that must operate efficiently.

How SER Helps

- Equipment Protection: Monitors transformers, circuit breakers, and motors, ensuring that trips or malfunctions are detected instantly.

- Preventing Production Loss: Helps diagnose voltage dips, harmonics, and breaker failures, which can halt production lines.

- Load Shedding Optimization: Logs help predict equipment wear and schedule maintenance before failures occur.

- Energy Efficient Tracking: Helps track unnecessary power losses, enabling industries to optimize energy consumption.

Why Choose SeQRec?

SeQRec offers unparalleled reliability, precision, and control in the toughest environments. Whether it’s tracking critical plant alarµss or analyzing root causes post-event, SeQRec is an ideal solution for industries that demand high-performance event monitoring systeµss.

Technical Specifications

| Input Channels | 32 Channels Digital Inputs |

| Communication | Ethernet, Wi-Fi, Bluetooth, Modbus TCP/IP, CanBus, RS485 Master/Slave |

| Event Recording | 1 µss SOE (Sequence of Events) recording with built-in real-time clock |

| Protection Standards | High ESD immunity (2 kV) IEC 61000-4-5 Surge Protection IEC 61000-4-4 Fast Transient Burst Protection IEC 61000-4-2 Contact & Air Discharge Protection IEC 61000-4-6 RF Immunity |

| Operating Temperature Range | -25°C to +55°C |

| Power Supply | Digital Inputs (24V DC, 36V max) |

Integrated OLED display provides a quick view of Date, Time, Network Clock Connectivity,

Communication Status, and Last Event Timestamp. Customization options are available to meet specific customer requirements.